Your cable or satellite TV quits. Your computer can’t connect. Your smartphone has one bar or says NO SERVICE. Frustration sets in, as there’s been a break in the telecommunication line due to a vehicle accident, storm, or construction excavation.

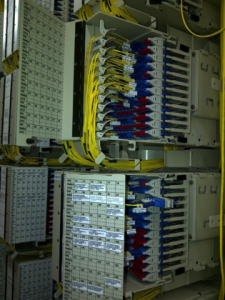

You probably don’t think about the millions of wire connections that keep your telephones, TV’s, and devices

working effortlessly. There’s a massive grid of panel boxes, underground cables, and data centers with lines that must be clearly identified.

When service re-connects, we exhale and thank a data center’s best friend, the label.

The technicians working in the datacom and telecom industries are avid label users. Their wire marking and labeling can be at fixed, internal stations or during off-site, in-the-field services. All data centers and networks have countless cables and connections and it is crucial that each wire termination is marked.

Field Services – Field service technicians carry portable printers carried in a vehicle. These printers can print labels, self-laminating wire wraps and shrink tube sleeves. They are favored by the telecom industry for the ease of marking small cables from 1/8” to ½” in diameter.

New Construction – Large cable tray labels are used for data cable identification and locations within new data/telecom buildings and plants. These wire and panel labels are typically printed from a PC-based, desktop label printer. Being able to import the data from a digital document or file directly to the label printer saves time and decreases errors.

Using label printers for data communications and telecommunications have become the standard for all electrical and electronic connections. This makes it easy for technicians and engineers to keep all data centers organized and operating efficiently, especially when lines are down. Telecom labels support our need to stay connected, just like a best friend would.

Help Desk Service – Contact us Between the Hours of 7:30 – 4:00 (MST)

Help Desk Service – Contact us Between the Hours of 7:30 – 4:00 (MST)