Wondering what’s involved in pipe marking throughout a commercial or industrial facility? Piping systems are used to transport different hazardous chemicals and substances in a facility. Though these pipes may be built according to stringent design standards, their maintenance and operation can be dangerous to the environment, the general public and of course, workers.

Pipe Labeling Regulations

It’s reported that almost 90 percent of all piping systems use the ANSI/ASME 13.1 standards for pipe labeling. Why are these standards required? They reduce the probability of error, promote safety, and deliver a reliable system to identify piping contents.

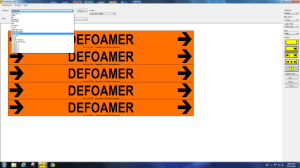

The ANSI color codes are a critical aspect of these regulations. The chemical/substance flowing through the pipe determines its color code. These labeling standards are based on 6 standard colors as well as 4 user-defined colors. Both the background and text colors form a part of the ANSI color standards and they should not be different from what is mentioned in the code.

The ANSI color codes are a critical aspect of these regulations. The chemical/substance flowing through the pipe determines its color code. These labeling standards are based on 6 standard colors as well as 4 user-defined colors. Both the background and text colors form a part of the ANSI color standards and they should not be different from what is mentioned in the code.

The following are several conditions that you should remember while arranging your pipe markers. According to the ANSI pipe marking standards, pipe markers should be placed:

- Alongside all flanges and valves

- On all sides of floor penetrations or walls

- After regular gaps

Pipe markers may not offer much help if they are too small or light to be seen. The greater the pipe diameter, the greater the pipe label should be.

If you would like help selecting the proper pipe markers for your situation, give us a call toll free at 1-800-268-7636. And… don’t forget to subscribe to our blog to be kept up-to-date on these regulations regarding industrial identification.

Help Desk Service – Contact us Between the Hours of 7:30 – 4:00 (MST)

Help Desk Service – Contact us Between the Hours of 7:30 – 4:00 (MST)