As part of the ongoing “Shine a Light On Our Supplier” series, Wayne Dembicki, Neumann Marking’s General Manager, recently sat down to speak with Renee Niederstadt, Senior Account Manager at Impact, Inc. Impact, Inc. is a manufacturer of wire marking and labeling systems primarily for the electrical industry. They have been in business in Seattle, Washington since 1989.

As part of the ongoing “Shine a Light On Our Supplier” series, Wayne Dembicki, Neumann Marking’s General Manager, recently sat down to speak with Renee Niederstadt, Senior Account Manager at Impact, Inc. Impact, Inc. is a manufacturer of wire marking and labeling systems primarily for the electrical industry. They have been in business in Seattle, Washington since 1989.

With this being their 29th year in business manufacturering, selling and servicing Advanced Wire Marking Systems (AWMS), we felt it was time to have a conversation.

Interview with Renee Niederstadt, Senior Account Manager at Impact

Wayne Dembicki (WD): Renee, thank you for taking the time to speak to me about your business.

Renee Niederstadt (RN): No problem Wayne, thanks for taking notice.

WD: Perhaps we could start with a short history of Impact.

RN: Sure. Dick and Rita Wellons started the company in 1989 selling dot matrix printers and formatted heat shrink wire markers mounted on fanfold paper. Around 1998, Dick was listening to his customer’s needs—they wanted faster, smaller and more portable equipment so he transitioned to thermal transfer printers.

WD: What models of thermal transfer printers do you offer?

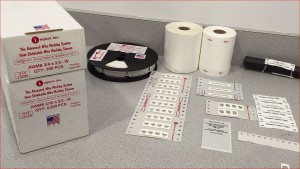

RN: Well, we have the bestselling AWMS-245 Plus and the AWMS-345 Plus. The difference between the two is printhead resolution. The 245 is 203 dpi and the 345 is 300 dpi. The AWMS-345C has the high resolution printhead and a cutter built in. The companion AWMS-225C completes our thermal printers. The AWMS-345C and the AWMS-225C are used for printing on continuous heat shrink tube or continuous label material. Customers who do not require preformatted material really like them.

RN: Well, we have the bestselling AWMS-245 Plus and the AWMS-345 Plus. The difference between the two is printhead resolution. The 245 is 203 dpi and the 345 is 300 dpi. The AWMS-345C has the high resolution printhead and a cutter built in. The companion AWMS-225C completes our thermal printers. The AWMS-345C and the AWMS-225C are used for printing on continuous heat shrink tube or continuous label material. Customers who do not require preformatted material really like them.

WD: Tell me about your heat shrink products.

RN: Our main line of heat shrink is a preformatted product. It is identified by inside diameter and then by length. We further distinguish it by shrink ratios; 2:1 or 3:1 and then by colour; white or yellow. In addition, we have continuous rolls of heat shrink in the 2:1 and 3:1 shrink ratios, white or yellow colour in 100 or 200 foot lengths.

RN: Our main line of heat shrink is a preformatted product. It is identified by inside diameter and then by length. We further distinguish it by shrink ratios; 2:1 or 3:1 and then by colour; white or yellow. In addition, we have continuous rolls of heat shrink in the 2:1 and 3:1 shrink ratios, white or yellow colour in 100 or 200 foot lengths.

WD: That must cover any job requirement. What do you attribute the success of Impact to?

RN: We feel it is because we are a company that cares. We care about our customers and how well our products work for them. When we speak to a customer who has a problem and we resolve that problem, they really appreciate being able to speak to a live person who can immediately get them up and printing again. Also, we listen to our customers. When they ask for something new, something different, we will try to get it for them and make it work in our printers. It helps them and we enjoy the challenge.

WD: Why do you give the Impact Wire Marking System software away for free?

RN: Everyone likes free and it works very well with our printers and supplies. Our customers appreciate the simplicity of using it and really like the end result. Sometimes simple is better.

WD: We have spoken about printers, heat shrink sleeves and software – what other printer products do you have?

RN: The newest item is flame retardant cable markers. This is a synthetic material preformatted on a roll to work in the AWMS-245 Plus and AWMS-345 Plus printers. You print, remove the tag and attach it to a cable with tie wraps. So, whether your cable is small or large in diameter, you can attach this tag. Oh, and don’t forget the self-laminating wire markers; these are gaining in popularity where heat shrink may not be required. Datacom applications are an additional market for the self-laminating wire markers.

WD: Renee, our time is up. Thanks for speaking with me and happy 29th anniversary!

RN: You are welcome. Remember everyone, “Say it with Impact”.

Want to see the Impact Heat Shrink Sleeve Printer in action? Check out the below videos.

To find out more about the Impact products that Neumann Marking Solutions offer…

Help Desk Service – Contact us Between the Hours of 7:30 – 4:00 (MST)

Help Desk Service – Contact us Between the Hours of 7:30 – 4:00 (MST)